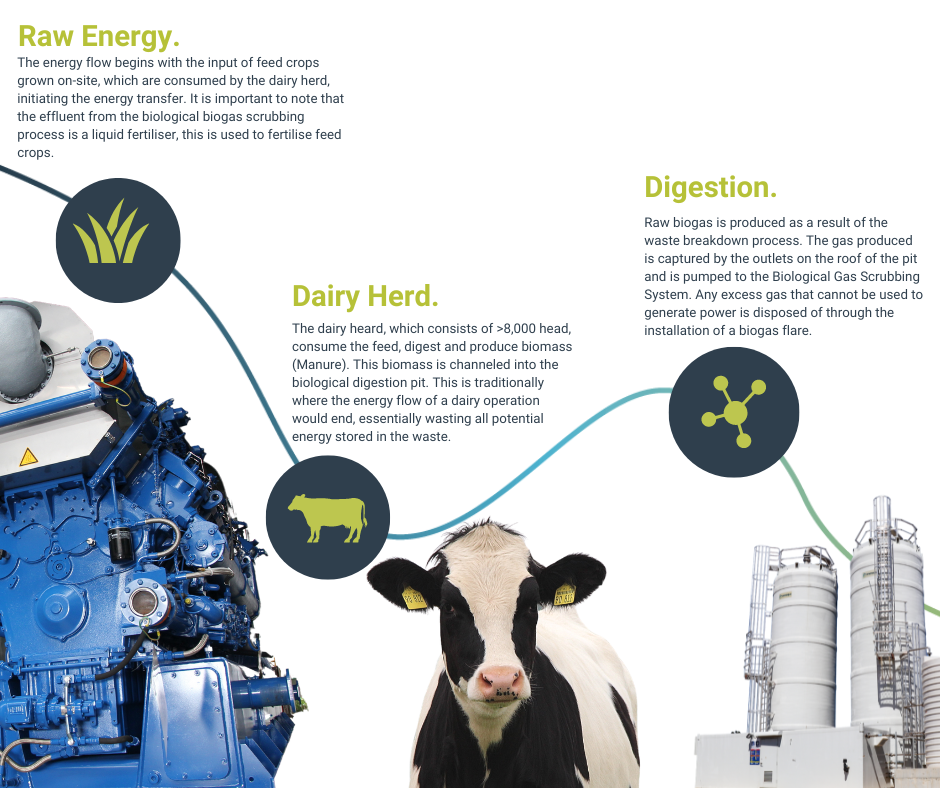

Project Overview:

Eneraque were approached by one of Australia’s leading mega-dairies to provide a bespoke, turn-key system to convert on-farm waste to energy. This project harnessed the energy value of cow manure to generate electricity, providing the farm with 100% of it’s energy needs while handling on-farm waste disposal.

Eneraque’s solution consisted of a state of the art Power Generation Plant. This custom technology, designed, engineered and built in Australia by the team at Eneraque, is a closed loop system, which feeds directly back to power the farms’ operation, with any extra power capable of being exported to the grid.

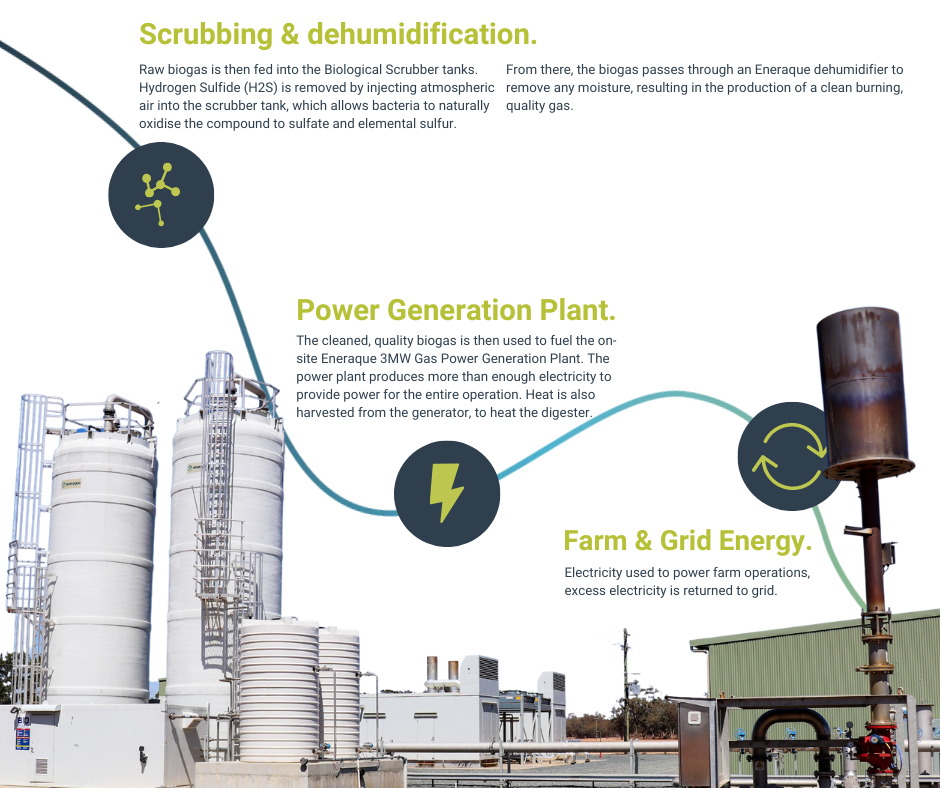

Biogas Scrubbing.

The Biogas System is comprised of several components. Major components include the primary blower, emergency flare, biological gas scrubber, dehumidification system and final blower. This complete system is capable of handling up to 1500m3/hr of saturated biogas with CH4 content of 54% and up to 4000ppm of H2S.

Power Generation Plant.

The Generator is powered by two MWM TCG2020v16 engines, producing 1564 kWe each, providing a total output of 3128 kWe.

The engine efficiency when running on biogas when commissioned is 42%, being one of the most efficient engines on the market for this application. It is a 16 cylinder, 71L engine and operates on gas as low as 5 kpa.

Project Highlights:

- Harnessing reliable, renewable energy.

- Custom, turn-key solution with excellent results and quantifiable commercial advantages.

- Delivery of the largest project of it’s kind in Australia.

- Minimal interruption to the client’s business.

Table 1: Design data vs actual gas treatment breakdown.

Project Outcomes:

- Extremely satisfied client.

- Timely installation.

- Closed loop system that allows the client to be energy independent.

- Excellence in Design Data vs Actual Gas Treatment Results.

- Excellent results from first service.

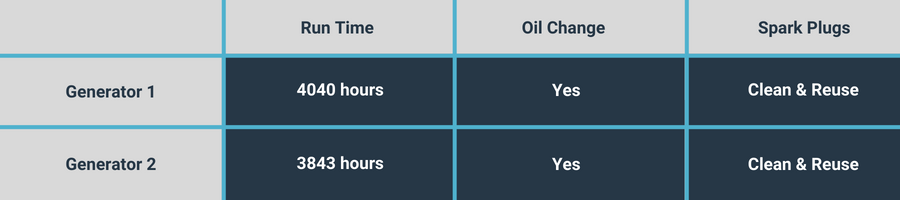

Table 2: Excellent results from the first Generator Service at this mega Australian dairy farm.

Project Specs:

- 3MW Gas Power Generation Plant.

- Two MWM TCG2020v16 engines

- Custom Biogas Scrubbing System capable of handling up to 1500m3/hr of saturated biogas.

- Primary Blower

- Emergency Flare

- Biological Gas Scrubber

- Dehumidification system

- Final Blower

For more information on this project please do not hesitate to reach out to our team of waste to energy specialists.