As the price of ‘green gas’ in Australia decreases, Waste Gas to Grid infrastructure projects are becoming viable and economically sound alternatives to other renewable energy sources such as solar and wind.

Eneraque has successfully operated in the renewable energy space for over 40 years, and is now incredibly proud to be pioneering biogas upgrading technologies on Australian soil. This pilot program will see Eneraque engineer, supply and install a biogas upgrading plant to Sydney Water’s Malabar Wastewater Treatment Plant, where it will transform raw biogas harvested from the anaerobic digestion of effluent into pipeline-quality renewable natural gas (RNG).

Biogas upgrading has gained significant traction across Europe and the US, namely due to more advanced sustainable initiatives and the only real prerequisite being a reliable source of biogas.

Eneraque is incredibly excited to advance these technologies locally, and pave the way to a greener future in metro and regional areas of Australia.

What is biogas upgrading?

Biogas upgrading refers to the processing of raw biogas to remove any impurities and moisture, to transform it into high-quality biomethane that meets the stringent gas specification requirements stipulated by the gird infrastructure provider. This purified gas is then blended into the gas grid network.

Biomethane is a clean form of biogas consisting of ~98% methane.

What is the biogas upgrading process?

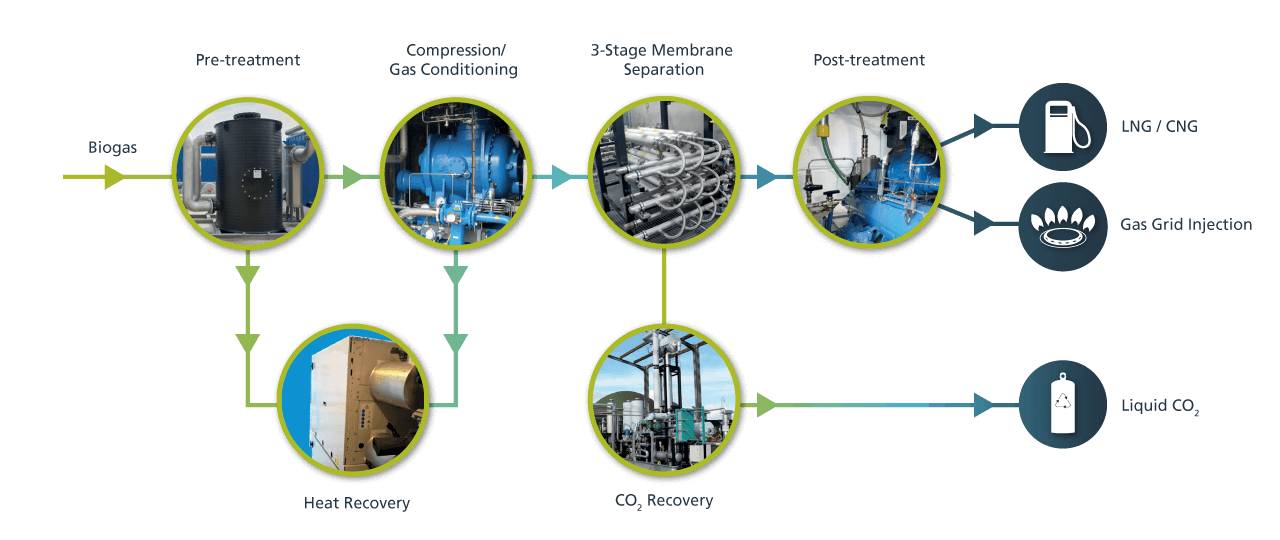

The current upgrading process utilised by Eneraque takes advantage of advanced membrane technology. A summary of the process is as follows:

Pretreatment – The raw biogas enters the plant, is cooled and dehumidified, before removing Volatile Organic Compounds (VOC’s) and Hydrogen Sulfide (H2S) through the use of activated carbon filters.

Compression – The pre-treated biogas is then compressed to the required pressure for the final upgrading process.

Upgrading Process & Control – The upgrading section of the plant can consist of a 2 or 3 stage membrane system, whereby CO2 and biomethane are separated into concentrated gas streams for final processing. Biomethane is then purified to network quality and CO2 is reprocessed for maximum biomethane recovery. Depending on the application, CO2 can be recovered for industrial users.

Injection/Blending – Once the biomethane reaches the desired specification, it is blended with natural gas within the gas network.

This process occurs seamlessly with minimal downtime and consistent monitoring by an intelligent control system, ensuring the safe, continuous and uninterrupted plant operation.

What are the benefits of biogas membrane upgrading technology?

There are a range of benefits that to the utilisation of membrane-based biogas upgrading, which play on both operational and financial factors;

Simple & Robust – Membrane-based upgraders are easy to maintain and reliable, with a limited number of moving parts. This keeps servicing and maintenance costs down as well is reducing headaches when the plant is operational. Further to this, increased uptime directly correlates to increased revenue. Extensive pre-treatment allows the membranes themselves to serve for extended periods of time, again reducing operational costs.

Consistency & Control – Maintaining control over the output quality of the gas is essential and is made easy by the constant presence of the membrane. This technology is unaffected by chemical imbalances.

Adaptable – As long as the gas is processed at the correct pressure, the biomethane output volumes of the membrane-based biogas upgrading plant can scale according to the input of raw biogas.

Dimensions – Membrane-based biogas upgraders offer a small footprint.

Economical – A high quality, cost effective solution to biogas upgrading with CAPEX and OPEX benefits, contact us to learn more…

Contact our friendly team and discover how an Eneraque Biogas Upgrading Plant can reduce your carbon footprint, create a passive revenue stream and enhance your operation.