Eneraque’s proven membrane technology achieves more than 97% operational availability.

The Biogas Upgrading System is easily integrated with a biogas plant, providing a refined, efficient method of gas cleaning, a robust design, an advanced patented control system and the assurance of 24/7 service support.

Eneraque’s advanced design and patented control system facilitate the injection of specification compliant biomethane to grid within a few minutes of start-up. Depending on your application, the Eneraque’s Biogas Upgrading systems can output gas to be used as transport fuel (CNG). Many other technologies in this space are subject to Methane loss and operational inconvenience as a result of slow start-up times, a factor which is of little concern when operating an Eneraque system. Reduce downtime and energy loss, maximise output and efficiency.

Eneraque’s Biogas Upgrading Systems offer an impressive 99.5% Methane recovery, minimal electricity consumption (0.22 kWh/Nm3 biogas) and require no thermal assistance (Heat) to keep the biogas upgrading process moving forward. An intuitive heat recovery unit (> 0.25 kWt/Nm3 biogas) covers the main energy consumption of the biogas facility.

Designed to be both high quality and competitively priced, Eneraque’s Biogas Upgrading Systems are value-engineered to provide the most economical solution.

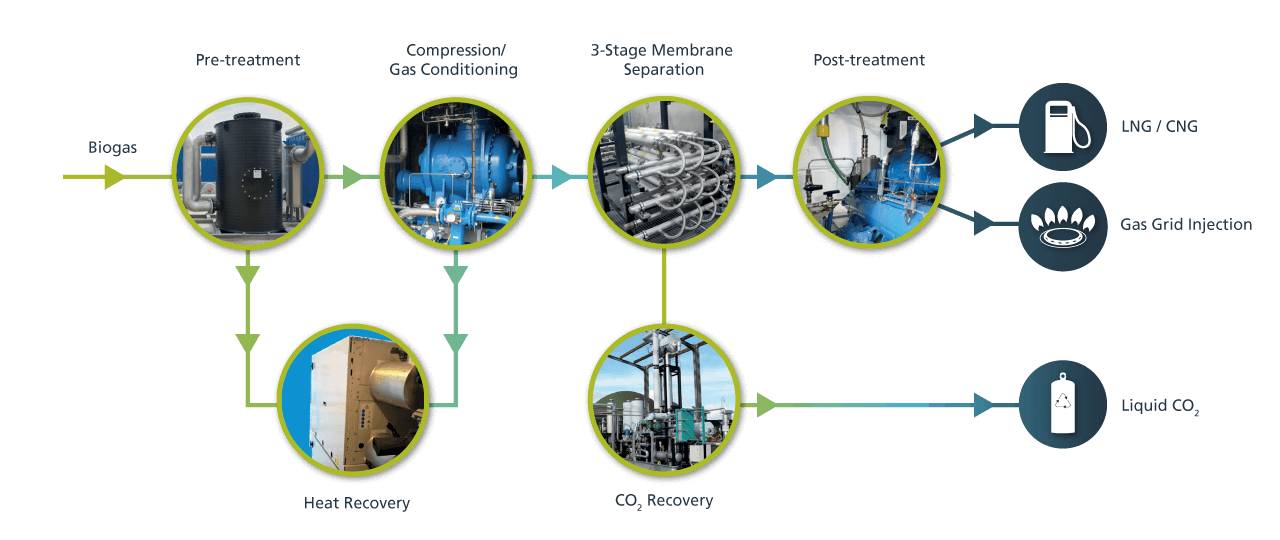

The provision to integrate CO2 recovery units into both the 2 and 3 stage membrane systems allows for the option to efficiently separate and liquefy CO2 with minimal energy consumption, much lower than conventional systems.

Eneraque’s process alleviates the need for chemicals and therefore eliminates the acid water/chemical disposal headaches and unforeseen costs associated with other more traditional systems.

Eneraque is experienced in managing biogas produced from most forms of biomass feedstock, including municipal sludges and wastes. Based on this experience, reliable biogas pre-treatment solutions can be offered to ensure the correct biogas specification is achieved before upgrading.