Project overview

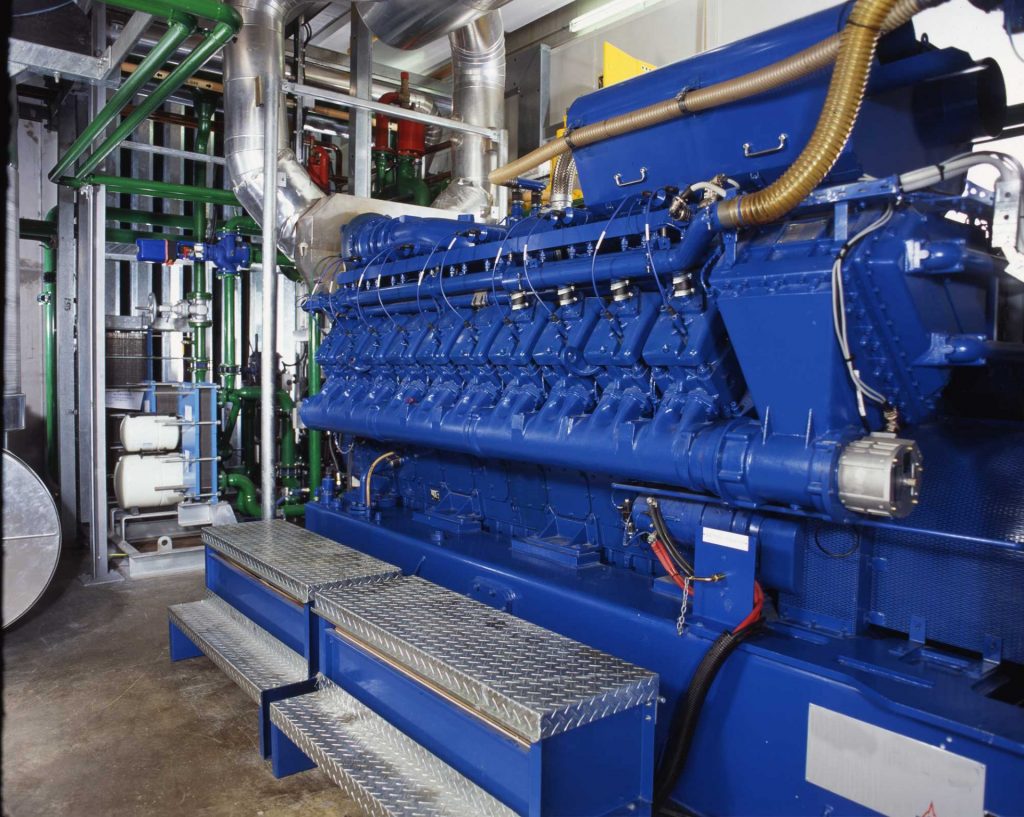

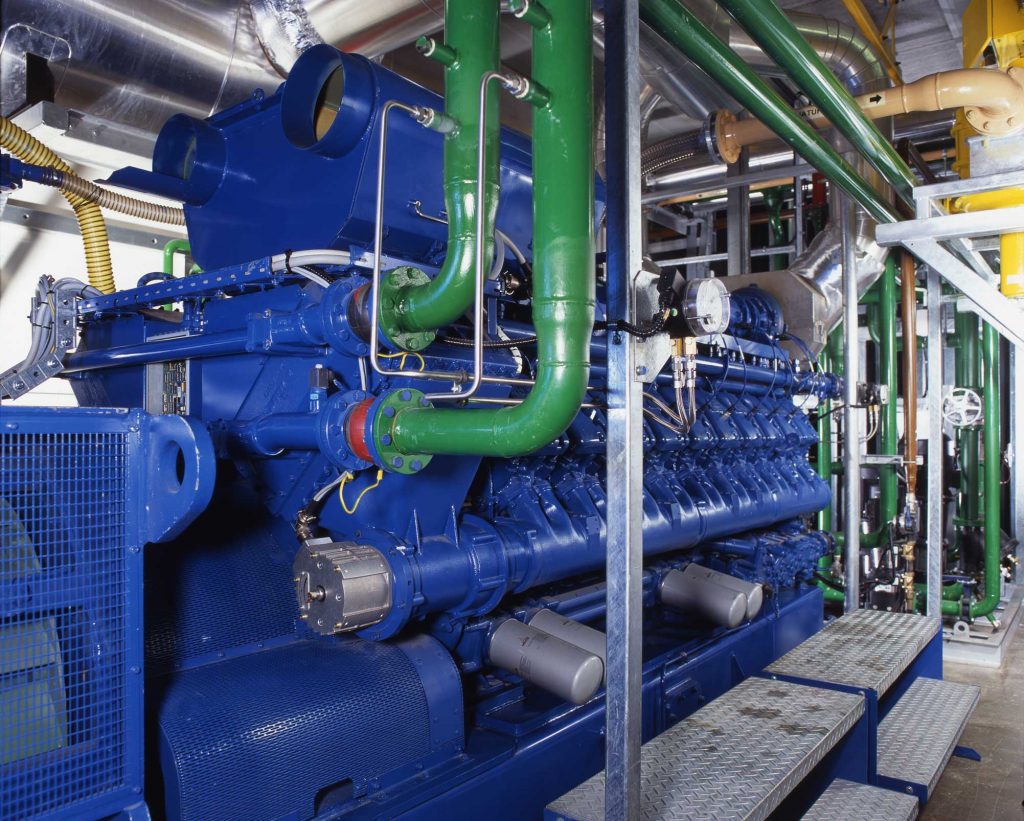

Eneraque covered the engineering, design, procurement, and construction of the Auckland Hospital Cogeneration and Stand-By Power Plant comprising two new 1.9 MW MWM TCG 2020V20 gas engine cogeneration units and one new nominal 1.8 MW MWM 620 v16 standby diesel generator. Eneraque project managed, manufactured, inspected and tested at Eneraque’s premises, packed for shipment, delivered to Site, installed, site tested and managed the defects liability period of the Auckland Hospital Cogeneration and Stand-By Power Plant. The cogeneration facility was installed inside an existing building adjacent to the existing Central Energy Plant at Auckland Hospital. The gas engines were fueled by natural gas and operated continuously and/or in peak lopping mode in conjunction with other Hospital energy plant to follow the hospitals electrical and thermal loads. The complete installation had to interface to many Hospital services and the supply of equipment to suitClient Need

To have one contractor to install the equipment into existing rooms and interface on all terminal points within the Hospital environs without disrupting the hospital operationOur Solution

The equipment used was MWM gas engines and MWM diesel engines providing some commonality in the brand but selected because of MWM’s high performance, stringent emissions and ease of maintenance. The complex control system built in house interfaced with the Hospital’s SCADA The solution included- Natural Gas Supply

- Existing and additional Diesel Fuel Supply

- Hot Water loops at multiple points

- Exhaust Systems

- Make up Water Supplies

- Building Penetrations for Acoustically treated Ducts

- Lube Oil Supplies

- Multiple LV Switch Boards

- Earthing Connections and Neutrals

- Protection and Metering Panels

- 11kV Switchgear

- Fire And Gas Detection

- Hospital SCADA

Our Approach

Eneraque approached this project with the intent to help all stakeholder involved in the project to produce a reliable and safe outcome. Eneraque met with the Hospital Board personnel on-site in order to gain a great understanding of their needs. From there Eneraque worked with the hospital board and engineers to finalize the project without harm or disrupting the hospital operation.Solution Turnaround

Eneraque delivered the project in just over 12 months which aligned with the client’s time-frame. Eneraque’s portion of the works aligned with the project time-frame, with no major notable delays.Outcome

When the plant was handed over to the client they were provided with a fully automatic system that was very user-friendly and reliable, delivering the energy both electrical and thermal to match the Hospitals requirementsAdditional Information

All the equipment was designed and manufactured by Eneraque to fit into the existing spaces provided by the client which were tight, still providing ample maintenance areas.Ready to reach your energy goals?

Backed by more than 40 years' experience, our specialist team are ready to power your energy project forward.