Eneraque Renewables‘ biogas upgrading technology has been featured in this month’s Energy Magazine.

A stand out in the article is the EnerSphere™ gas storage dome, Eneraque Renewables’ double membrane gas storage dome enables the storage of significant quantities of different gases and planned biogas storage.

The featured project is the Malabar Biomethane Injection Plant,

Eneraque Renewables provided the Biogas Upgrading Equipment for the project, a robust design developed from many years of successful application across Europe, Asia and the USA.

This Australian first biomethane upgrader takes biogas sourced from existing anaerobic digestion infrastructure at Sydney’s Wastewater Resource Recovery Plant and upgrades this to pipeline quality biomethane. The Upgrader is sized for 1100Nm3/hr of biogas to the inlet prior to separating the CO2 and CH4 with a patented 3-stage membrane technology from our partners, Evonik.

The biomethane is then injected into the gas grid at high pressure to pipeline quality specification. The technology features an advanced patented control system, continuous process monitoring, remote operation and 24/7 support.

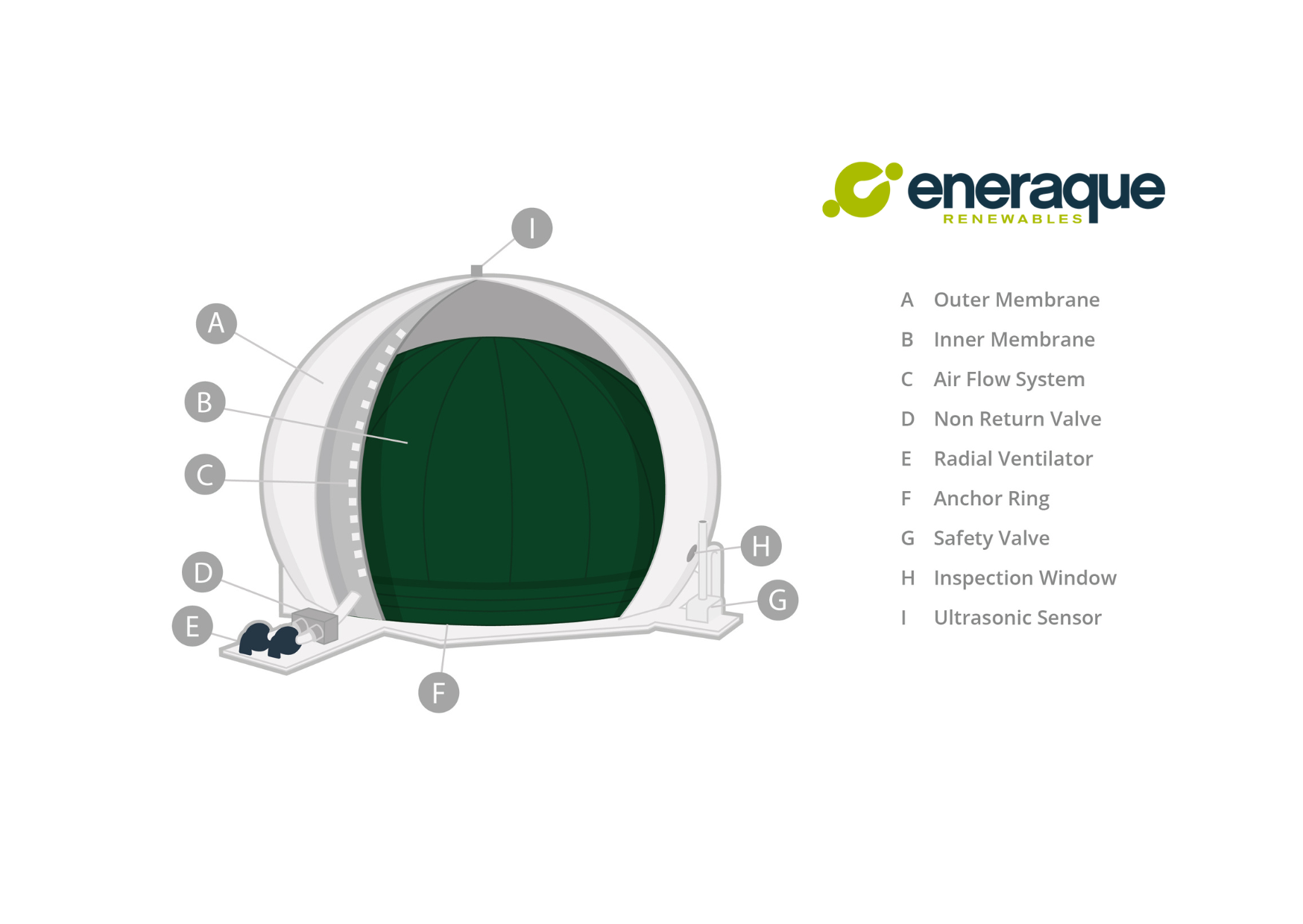

About the EnerSphere™

Eneraque Renewable’s range of superior biogas storage tanks enables the storage of significant quantities of different gases. These biogas storage systems allow planned biogas storage so that generation plant managers can gather sufficient quantities of fuel in the event of planned export to the grid at a peak price point to optimise revenue.

In the event that a generator is off-line for maintenance, the biogas storage facility will enable maximum gas utilisation.

The biogas storage tank membranes are highly tear resistant polyester fabrics with a special PVC surface treatment and acrylate varnish.

- Biogas storage system fabric is highly flame-proof according to DIN 4102-B1

- Higher specification fabric is available on request

- The special surface treatment formula guarantees high resistance against permeability & UV

- All biogas storage tanks are resistant to wind and heavy snow and guarantee safe operation

- The temperature resistance ranges from –30°C to +60°C