From single pieces of Biogas Equipment to entire Plants, Eneraque Renewables can offer complete Biogas solutions for your business.

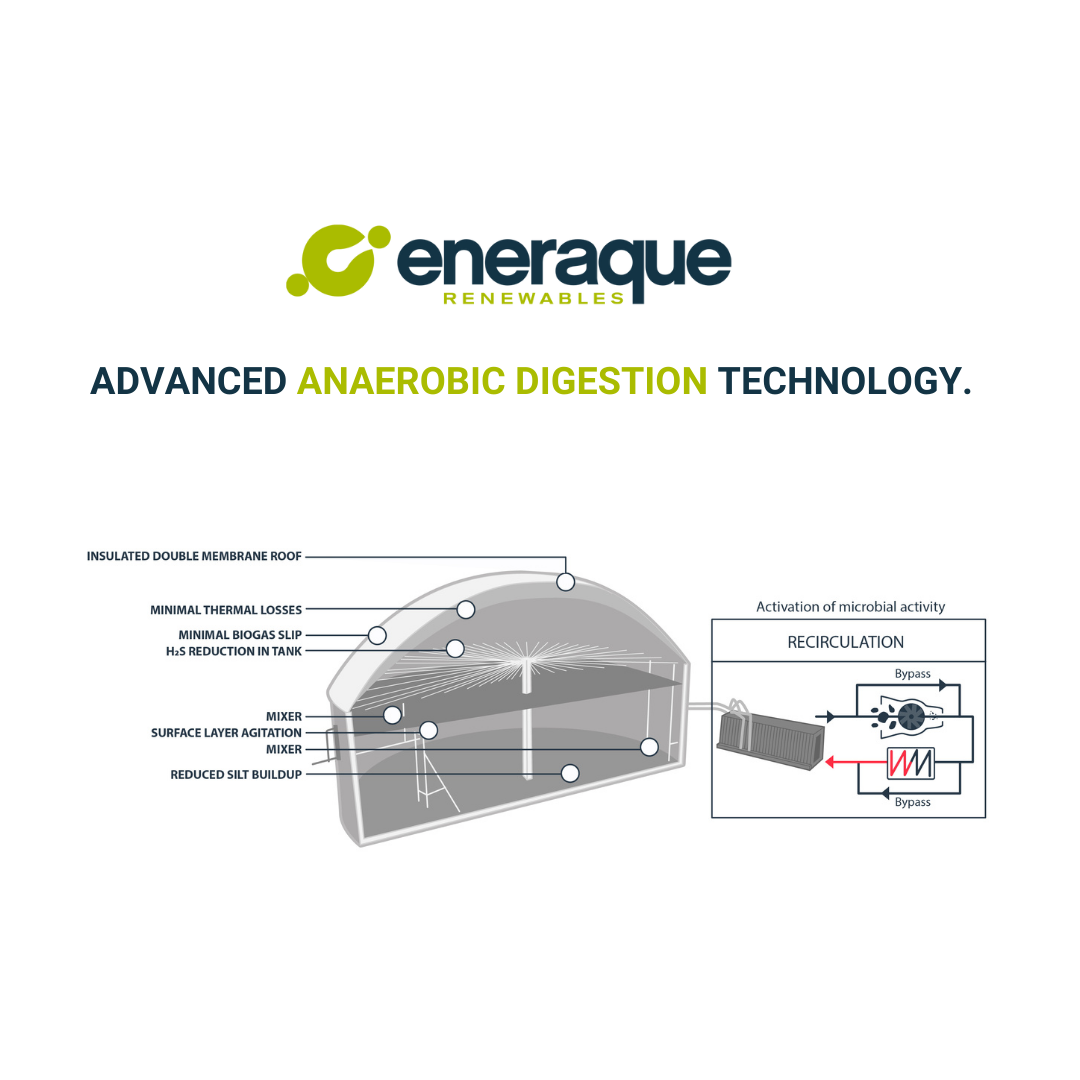

Embarking on a journey through the inner workings of a biogas plant unveils a complex network of equipment, processes, and systems meticulously designed to maximise energy production, minimise environmental impact, and support the circular economy. From the heart of the operation—the anaerobic digester—to the safety measures and environmental compliance systems ensuring responsible operation, each component plays a vital role in the harmonious workings of this renewable energy system.

Anaerobic Digester: This is the core component where organic materials undergo anaerobic digestion. The digester can be of various designs such as batch, continuous stirred-tank reactor (CSTR), plug flow, or fixed-dome. It provides an oxygen-free environment for anaerobic microorganisms to break down organic matter.

Mixing System:

-

- Mechanical Mixer: Rotating blades or paddles ensure proper mixing of feedstock and microorganisms within the digester, preventing sedimentation and promoting efficient digestion.

- Hydraulic Mixer: Uses the flow of biogas or liquid within the digester to achieve mixing without the need for mechanical parts.

Gas Collection System:

-

-

- Gas Collection Pipes: Network of pipes installed within the digester to capture biogas as it is produced.

- Gas Storage Tanks: Tanks or reservoirs where collected biogas is stored temporarily before utilisation.

- Gas Meters: Devices used to measure the volume or flow rate of biogas produced, aiding in monitoring and control.

-

Gas Purification Equipment:

-

-

- Gas Scrubbers: Remove impurities like hydrogen sulfide (H2S) from biogas by passing it through a scrubbing liquid.

- Chemical Treatment Units: Utilise chemicals to remove contaminants from biogas.

- Gas Dryers: Remove moisture from biogas to prevent corrosion and improve its energy content.

-

Gas Utilisation Equipment:

-

- Engines: Biogas-powered internal combustion engines that drive generators to produce electricity.

- Turbines: Biogas drives turbines to generate electricity.

- Generators: Convert mechanical energy from engines or turbines into electrical energy.

- Burners: Utilise biogas for heating applications, such as in boilers or stoves.

Digestate Storage Tanks: Tanks used to store the residual organic material (digestate) after digestion. The digestate can be further processed and used as organic fertiliser.

Effluent Treatment System:

-

- Settling Tanks: Allow solid particles in the effluent to settle, separating the liquid portion.

- Aerobic Treatment Units: Some plants use aerobic processes to further treat the liquid effluent, reducing its organic content.

- Nutrient Recovery: Additional processes to recover valuable nutrients from the effluent for use as fertilisers.

Control and Monitoring System: Automation and monitoring systems regulate various parameters within the biogas plant, ensuring optimal conditions for digestion, safety, and performance.

Safety Measures:

-

- Gas Leak Detection Systems: Monitor for leaks of biogas, which can be flammable and hazardous.

- Ventilation Systems: Provide proper ventilation in enclosed spaces to prevent the buildup of potentially harmful gases.

Infrastructure: Access roads, fencing, lighting, and other facilities necessary for plant operation, maintenance, and security.

To discuss your bioenergy system, from single pieces of equipment to entire plants, contact our specialist team.