Project overview

To design and provide a fully automated remote power station capable of automatically dispatching and loading generators as demand requires, with the capacity to operate reliably and efficiently over the full range of the environmental conditions experienced at the site.Eneraque’s Solution.

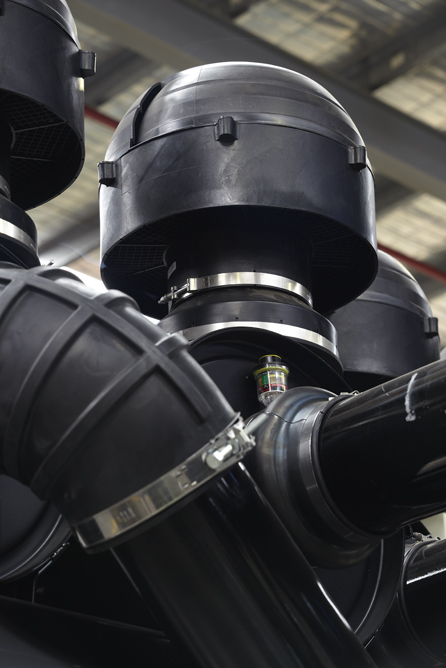

Eneraque successfully handled the design, engineering, procurement, project management, manufacture, works inspection and testing, supply packaging and protection, transportation, unloading, installation, site inspection, commissioning, site testing, reliability trials and all work related to the complete balance of plant equipment and services for the Power Station. Eneraque provided the following mechanical systems for the Power Station:- Fire protection, detection and suppression systems

- Firewater tank, fire pumps, fire water reticulation and hydrants

- Diesel storage and distribution system

- Plant and instrument air storage and distribution system

- Natural gas pipeline off-take and gas metering/letdown skid

- Distillate fuel storage tanks

- Fuel tanker unloading facility

- Lube oil unloading facility

- Waste lube oil loading facility

- Waste liquids collection facility

- Waste liquid offloading facility

- Diesel engine fuel and lube oil reticulation piping systems

- Gas engine lube oil and gas reticulation piping systems

- Diesel engine lube oil and gas spark ignition engine lube oil storage facilities

Outcome and benefits

The unit, once installed, was serviced and maintained by Eneraque, which ensured its availability to provide standby power at any given time.Ready to reach your energy goals?

Backed by more than 40 years' experience, our specialist team are ready to power your energy project forward.