By partnering with Eneraque to perform their signature 4 Day Gas Engine Top End Overhaul, one of Veolia’s major waste to energy (landfill) facilities has achieved significant performance gains from their biogas engine, without impacting daily site operations.

Located in Queensland, the facility is a leading example of sustainable waste management and renewable energy production, specialising in converting waste into biogas to generate electricity. As part of their ongoing maintenance and to improve resource efficiency, Veolia recently engaged Eneraque for their signature 4 Day Top End Overhaul of one of their gas engines (one of four) running on biogas collected from the landfill site. Based on the success of the Overhaul, Veolia have engaged Eneraque to perform all future Top End Overhauls for this site.

About our Signature 4 Day Top End Engine Overhaul.

Recognising that engine downtime can result in substantial revenue loss, Eneraque’s Asset Performance Team identified the critical need for an efficient Top End Overhaul procedure to maintain power generation availability targets without the extensive interruption to daily operations that this detailed procedure normally entails. Through a forensic analysis of the process, Eneraque have developed a unique procedure and methodology for the Overhaul, reducing downtime and being able to complete the process in just 4 days, significantly faster than the market average.

Project Background

The gas engine at this landfill site is a vital part of their energy generation process. It converts biogas from organic waste into electricity, which is used on site, with any excess supplied to the grid. In this application, cylinder head valve recession and siloxane build-up are common issues. These issues must be constantly monitored and efficiently addressed to prevent catastrophic engine failure, which could result in extensive downtime and significant revenue loss. A Top End Overhaul is essential to improve asset efficiency, however these are traditionally resource intensive and can interrupt operations, costing the Client time and money. Eneraque’s signature 4 Day Top End Overhaul was identified as the perfect solution for the Client’s Performance and Commercial objectives.

Objectives

- Reduce downtime: Perform the Overhaul as efficiently as possible to reduce downtime.

- Maintain Engine Performance:Maintain the engine’s efficiency and power output.

- Increase Reliability:Enhance the engine’s reliability and extend its operational life.

Scope of Work

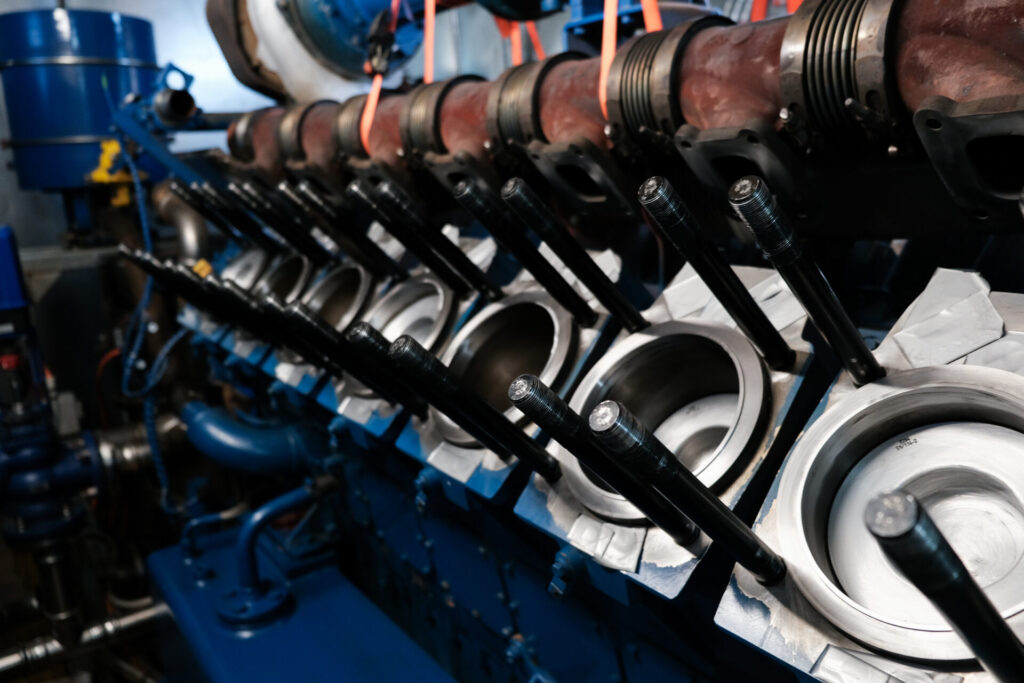

The overhaul focused on the following key components of the gas engine:

- Cylinder heads

- Valves and valve seats

- Pistons and bores

- Fuel injection system

Process

- Initial Inspection and Diagnosis:

- Carried out Valve set

- Conducted a thorough inspection of the engine.

- Performed diagnostic tests to identify areas of wear and tear.

- Disassembly:

- Carefully disassembled the engine’s top-end components.

- Catalogued and cleaned each part for detailed inspection.

- Component Evaluation:

- Inspected cylinder heads for cracks and warping.

- Checked valves and valve seats for wear and proper sealing.

- Assessed the condition of pistons, piston rings, and cylinder liners.

- Examined turbochargers and the fuel injection system.

- Machining and Replacement:

- Replaced cylinder head assemblies.

- Assessed and cleaned pistons.

- Reassembly and Testing:

- Reassembled the engine with precision.

- Conducted a series of tests, including compression testing and emissions analysis.

- Performed a break-in procedure to ensure proper seating of new components.

Results

The top-end overhaul of the biogas engine at Veolia’s facility yielded significant improvements and was able to be performed within 4 days, resulting in:

- Reduced Downtime:Our signature 4 Day Top End Overhaul avoided significant downtime, interruption to staff or operations

- Enhanced Efficiency:The engine efficiency was significantly improved.

- Increased Reliability:The overhaul extended the engine’s operational life and reduced the frequency of unscheduled maintenance.

- Future Partnership: The success of the Overhaul has led to Eneraque being selected as the Top End Overhaul Partner for this site.